Murexin

Large formats

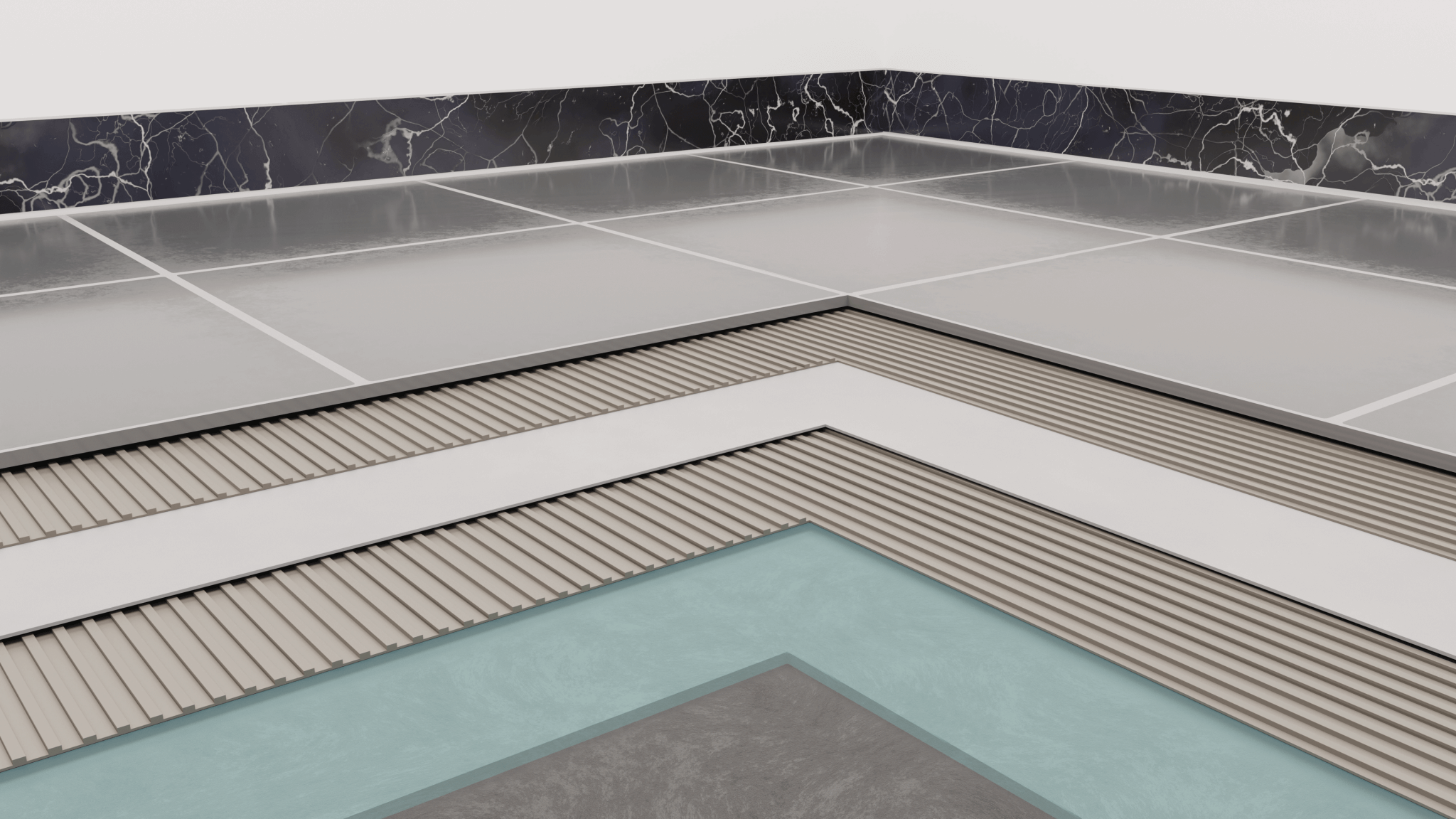

- 1 | PRIMER LF 1

- 2 | FLEX ADHESIVE MORTAR MAXIMO M 41

- 3 |

- 4 | FLEX ADHESIVE MORTAR MAXIMO M 41

- 5 |

- 6 |

As already described in the previous chapter, large and giant formats are on trend. Large formats are mainly used as the floor covering in residential buildings. They are recommended in fixed laying for indoor use only. Large formats for floors are defined as ceramic tiles according to EN 14411 with a minimum thickness of 7.5 mm, with an edge length of 60 to 120 cm and, in the case of interlocking formats, up to an edge length of 150 cm or a base area of < 0.25 m2. Since most such large formats are made of fine stoneware, a water absorption of less than 0.5 % by weight can be assumed – an installation material with non-absorbent properties.

The floor is an important component in building design, as this construction is not only assigned the load transfer from the surface load but also physical properties such as sound insulation and thermal insulation. Nevertheless, heated floating constructions are in the spotlight. Screeds are differentiated by binding agent, among others, e.g. as calcium sulphate screed (C/CAF) or as cementitious screed (CT).

In particular, the freshly laid screed has a waiting time until it is ready for covering, which is called residual moisture (operating moisture of the building material). Depending on the binding agent, different waiting times or concurrent measures such as sanding the surface or switching on the underfloor heating system are required. Once all measures have been completed in accordance with the guidelines, the residual moisture can be determined or measured. This can happen after 4 weeks for CT screeds (4 – 5 cm thick) and after 6 weeks for CA screeds (3 – 4 cm thick).

When laying the floor, CA screeds must generally be sanded beforehand. For both screeds (CT and CA), the following product combinations must also be used to prepare the substrate: water-based dispersion primer + fast-setting adhesive mortar (high crystalline water retention) or blocking primer (e.g. reaction resin) + fast-setting adhesive mortar [the latter for CA screeds only when the screed is ready for covering!]. As described in the previous chapter, the substrate preparation for a level surface and the rapid curing of the adhesive mortar during installation are important. The combined method of installation must be used (see also page 25, Giant formats). Covering joints should not be less than 3 mm wide. Edge, expansion and field boundary joints are to be arranged as required and carried out up to the surface of the laying substrate. In practice, boundary clearances of up to 5 m have proven successful. If the substrate or the combination of covering materials is deemed fairly critical, or if there is a need for stress relief, e.g. due to thermal load, then an additional decoupling measure is recommended.

PRIMER LF 1

PRIMER LF 1

FLEX ADHESIVE MORTAR MAXIMO M 41

FLEX ADHESIVE MORTAR MAXIMO M 41