Murexin

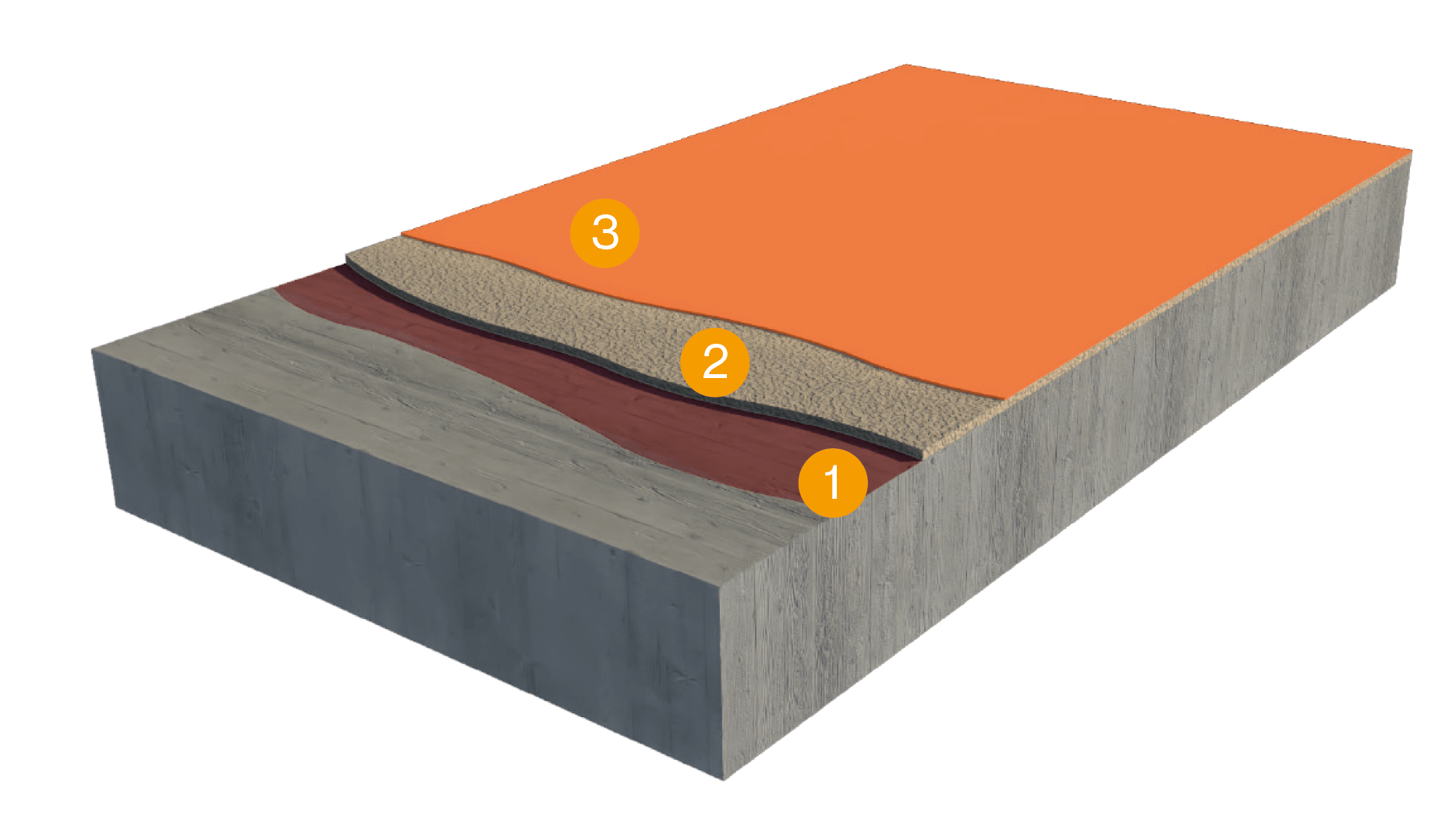

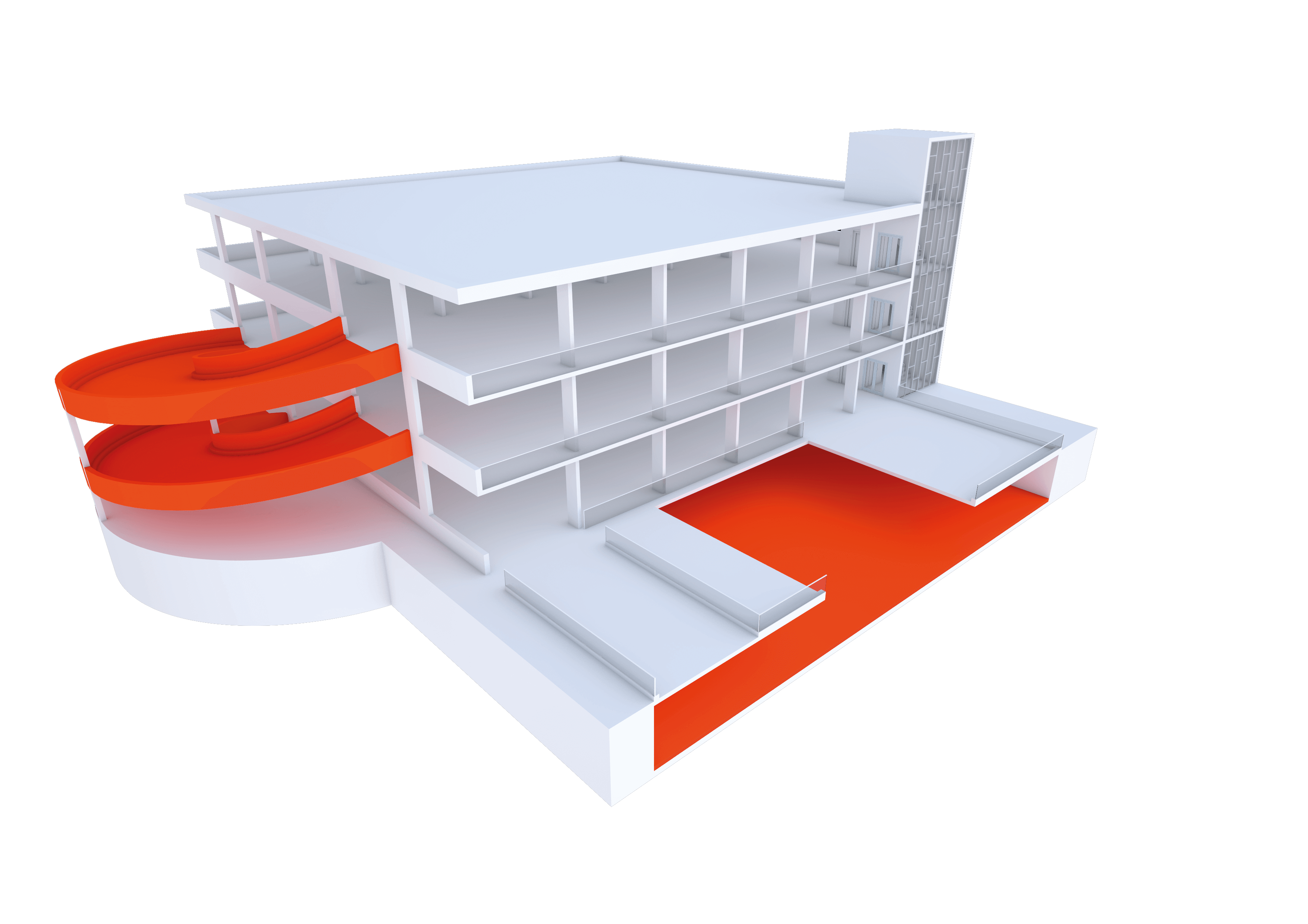

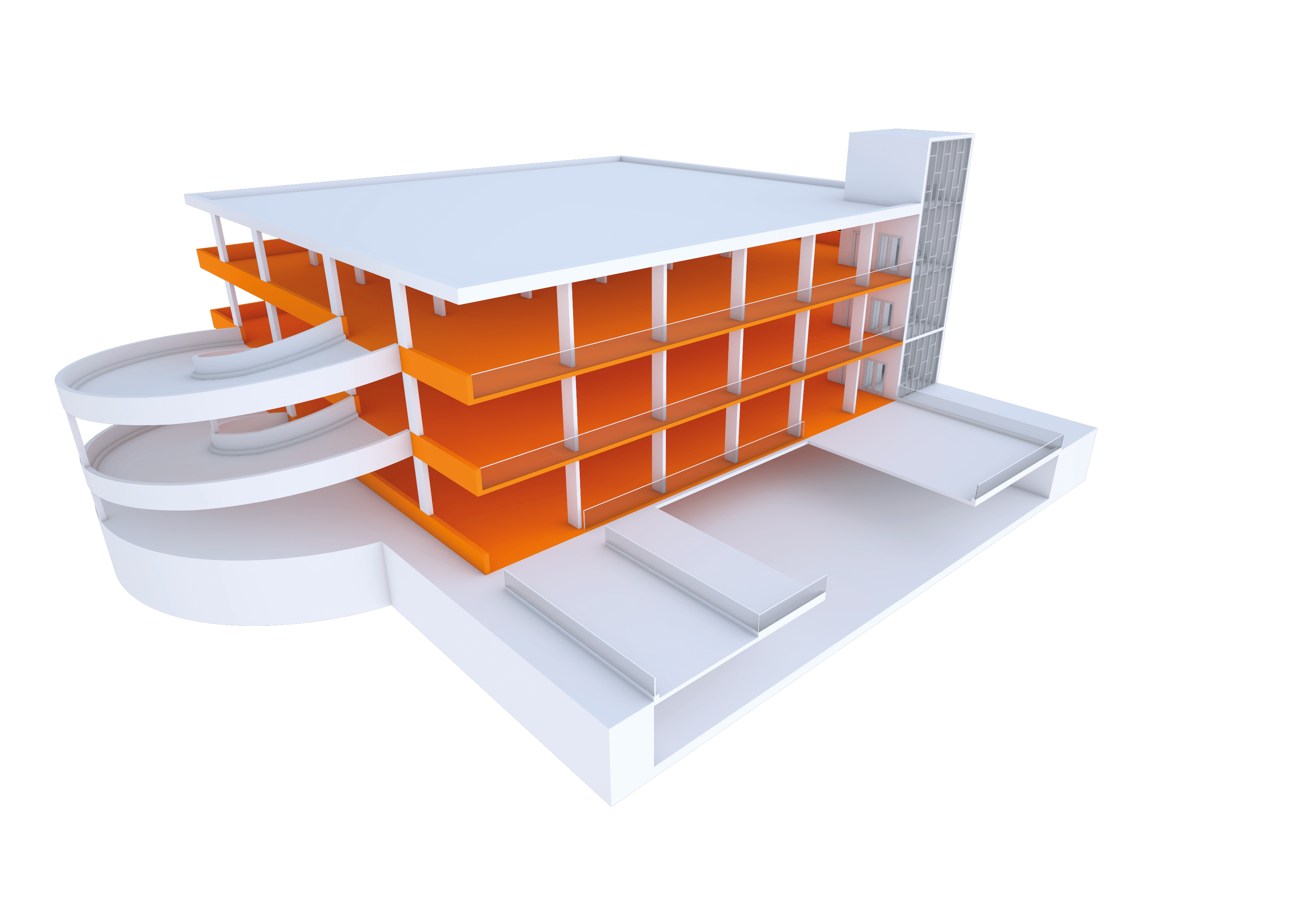

Parking garage construction

- 1 | Intermediate decks – OS 11b

- 2 | Ramps & spiral ramps – OS 13

- 3 | Ramps & spiral ramps – OS 8

- 4 | Ground contact area – OS 13 or OS 8

- 5 | CO2 brake wall and ceiling coating

- 6 | Sealing of corridor areas/staircases

- 7 | Markings

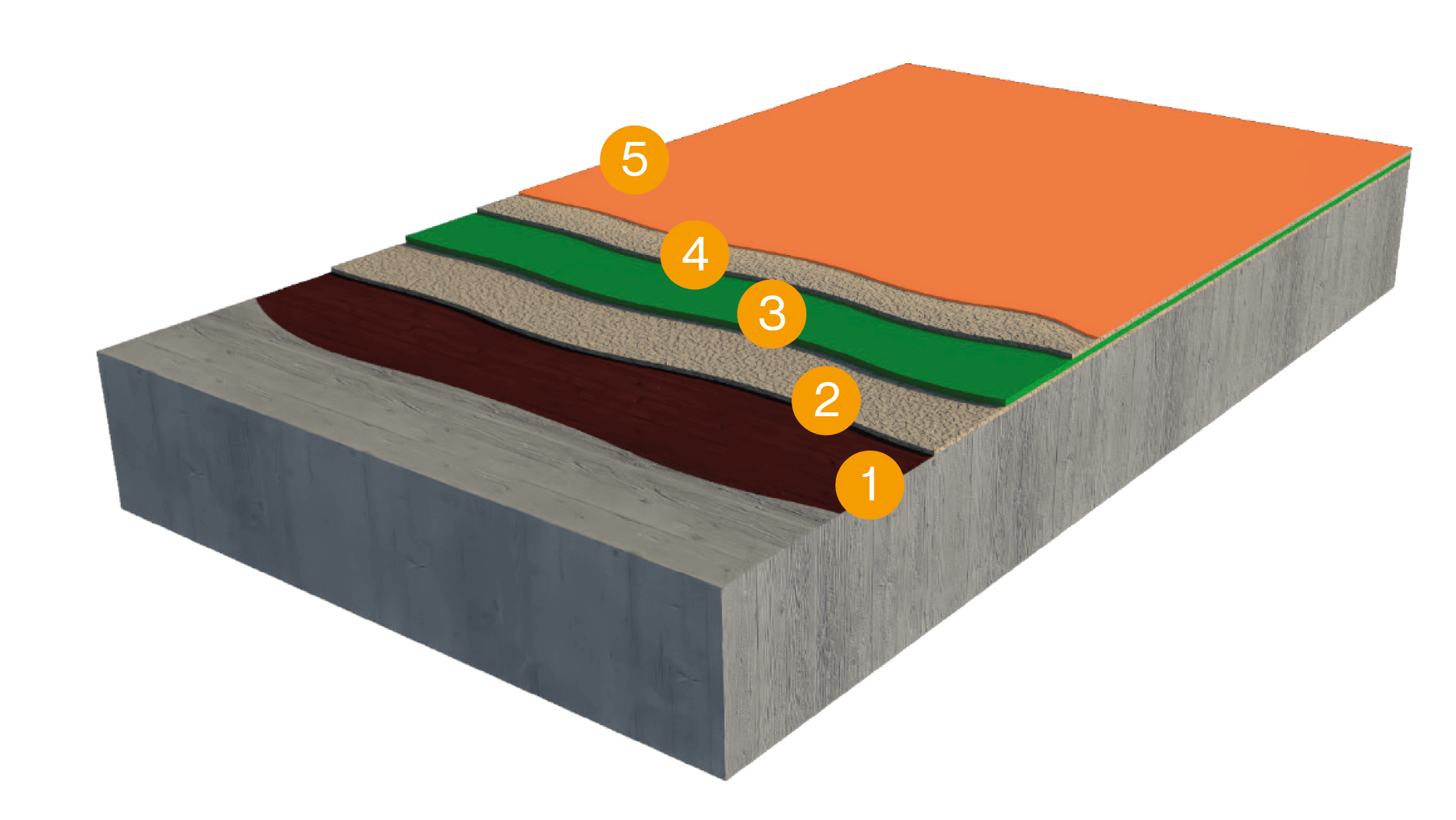

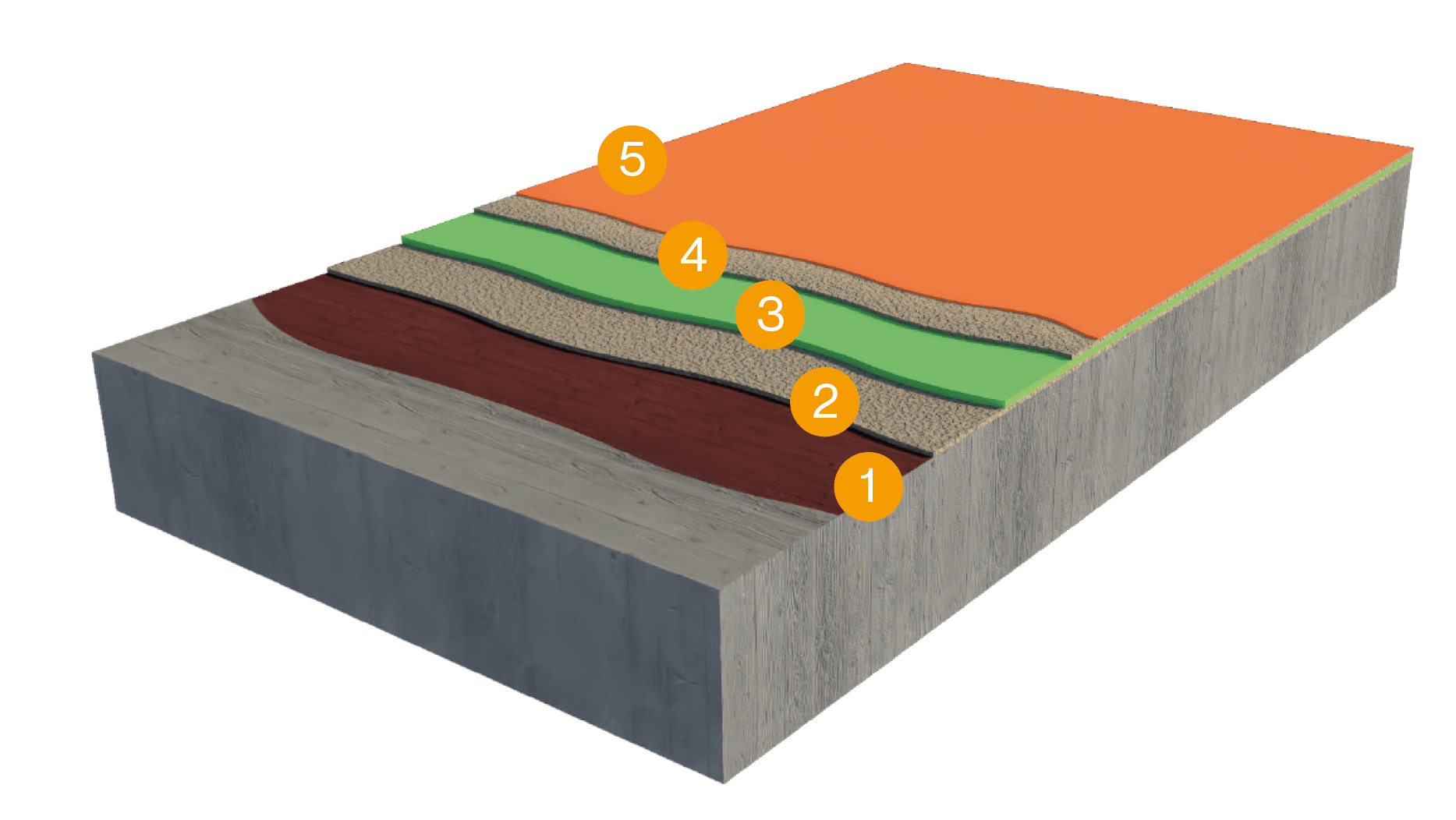

OS 8b System

1. Primer

Primer OG 80

Consumption: approx. 500 g/m2 Binding agent

dependent on the absorbency and roughness of the substrate Note: If necessary,Primer OG 80 can also be filled up to 50% with quartz sand 0.1-0.5 mm

Colour: transparent

2. Sanding off the excess

quartz sand (0.3 – 0.8 mm) consumption: approx. 4,500 g/m2

3. Head sealing

Epoxy primer EP 2

Consumption: approx. 900 g/m2

Colour: RAL of your choice

Moisture protection for floor panels

Internal driving and parking areas that lie at or below ground level are exposed to the risk of moisture penetrating from the ground, in contrast to the upper floors of a multi-storey car park. The trigger for this is the capillary effect, which allows rising moisture from the ground to penetrate into the structure. OS 8 is a system solution for protecting these surfaces. The thin-layer covering can be precisely adapted to the requirements of the local conditions, and thus represents an economical solution for the surface protection of areas in contact with the ground. If the pre-treated mineral substrades are not hard and close to the surface, we recommend impregnating or priming them with low-viscosity reaction resins.

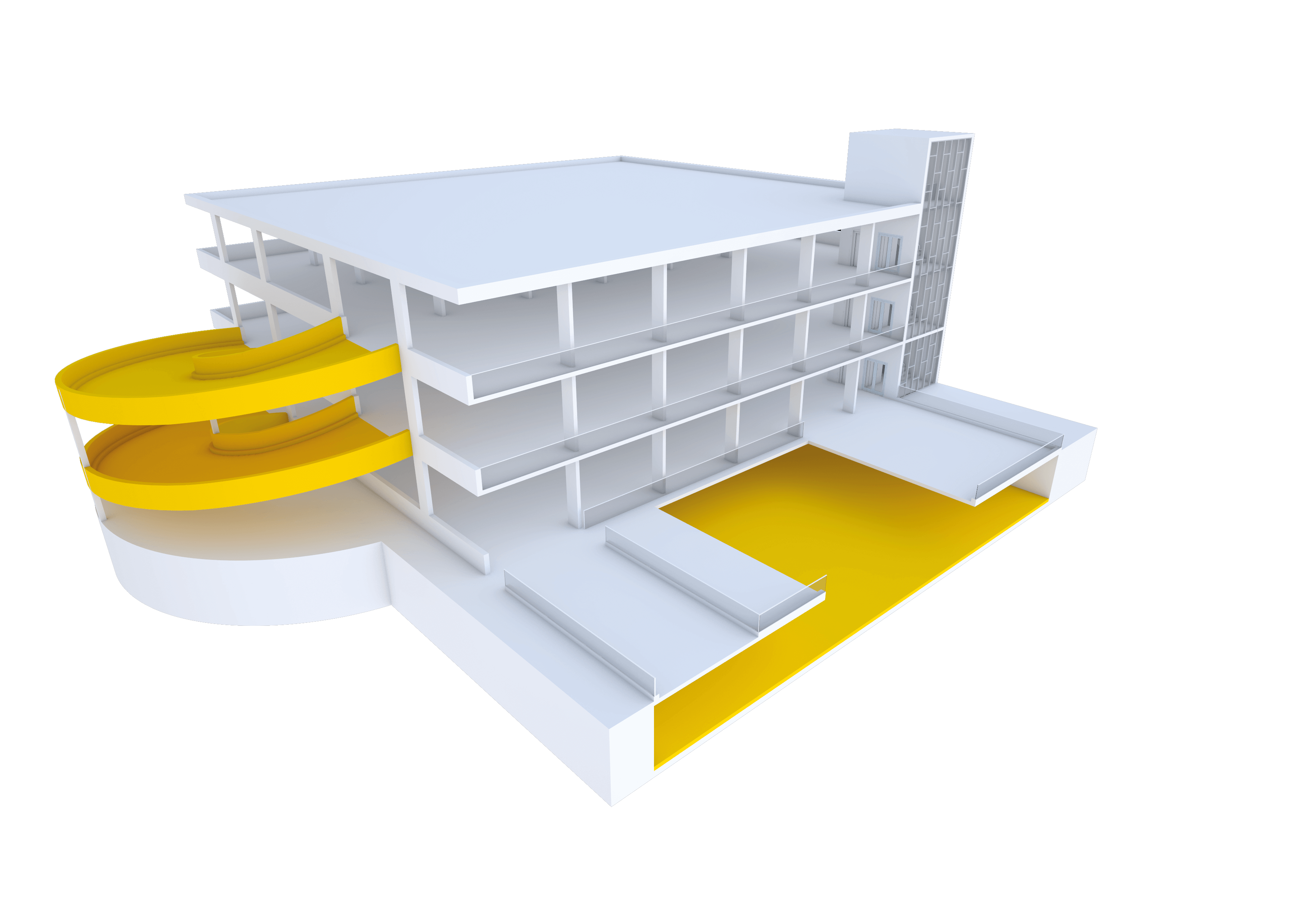

OS 13 System

1. Primer

Epoxy primer resin EP 70 BM

consumption: approx. 300 g/m2

2. Sanding

quartz sand (0.3 – 0.8 mm) consumption approx. 1,000 g/m2

3. Coating

Polyurethane coating PU 300

Consumption: approx. 1200 – 1300 g/m2

Colour: RAL of your choice

4. Sanding off the excess

quartz sand (0.3 – 0.8 mm) consumption: approx. 4,500 g/m2

5. Head sealing

Epoxy primer coating EP 2

Consumption: approx. 900 g/m2

Colour: RAL of your choice

Non-slip surface protection for driving ramps & spiral ramps

Spiral ramps and straight ramps are subject to much more stress, as higher forces act on their surfaces than on normal driving or parking areas. Mechanical protection is very important at these (narrow) spots in particular, where the risk of accidents is higher than in the rest of a multi-storey car park. OS 13 is the perfect solution for this. As a multi-layer surface protection made of thick, crack-bridging layers, it is both more resistant and non-slip.

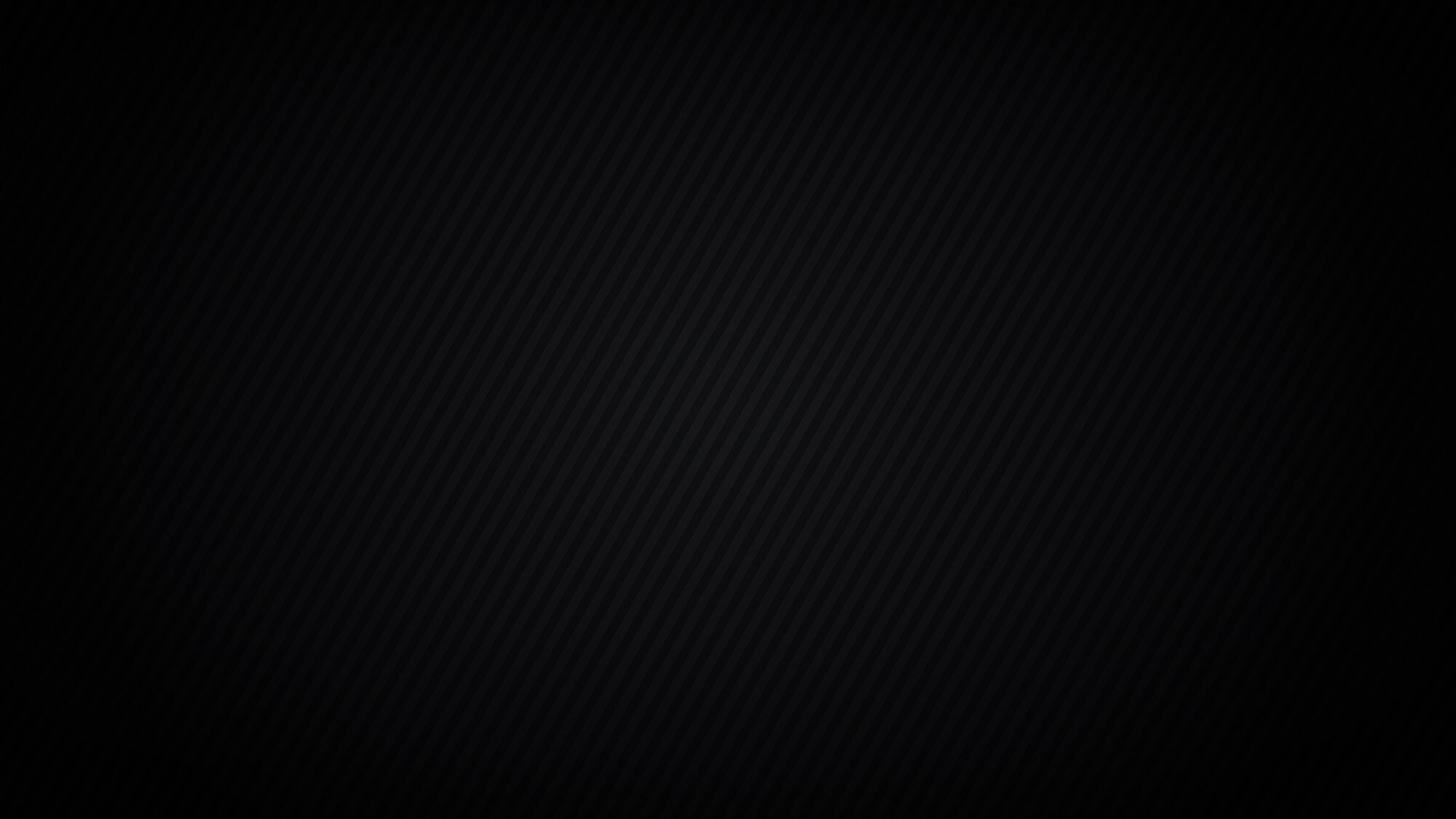

OS 11b System

1. Primer

Epoxy primer resin GH 50

Consumption: approx. 300 g/m2

2. Sanding

quartz sand (0.3 – 0.8 mm) consumption approx. 700 g/m2

3. Coating

Polyurethane coating PU 600

Consumption: approx. 1800 – 2500 g/m2

Filled with approx. 40% quartz sand 0.1-0.5 mm Consumption: approx. 700 – 1000 g/m2

4. Sanding off the excess

quartz sand (0.3 – 0.8 mm) consumption: approx. 4,500 g/m2

5. Head sealing

Epoxy primer coating EP 2

Consumption: approx. 750 g/m2

Crack bridging and non-slip surface protection on upper floors

With its elastic polyurethane layer, the OS 11b system solution ensures the highest level of crack bridging in the modules presented here. The structured surface improves the non-slip properties of driving surfaces of intermediate decks above ground level. The individual multi-storey car park floors can also be treated in different colours for good visual differentiation.