Murexin

Substrate preparation levelling

- 1 | CLEAN POLISH

- 2 | PRIMER LF 1

- 3 |

- 4 |

The substrates are not always level enough to allow tiling work to be carried out directly. This is the case both on the wall and on the floor. Tolerances regulated by standards (DIN 18202) are often not sufficient to produce a professional and visually flawless workmanship.

For the wall area, normal or fast-setting, stable levelling mortars are recommended to produce level surfaces. Cement-based rapid-reaction products are best suited for the tiler.

In the floor area, both stable mortars and self-levelling filling compounds can be used for levelling the substrate, which are distinguished by reactivity and binding agent. The two main binding agents of the aforementioned products are gypsum and cement. The areas of application of the respective products can be found in the technical descriptions.

Sometimes thicker layers are needed, which the tiler has to apply themselves and at a incline, e.g. in the base area of a flush-to-floor shower. Special and fast-reactive screeds are particularly suitable here.

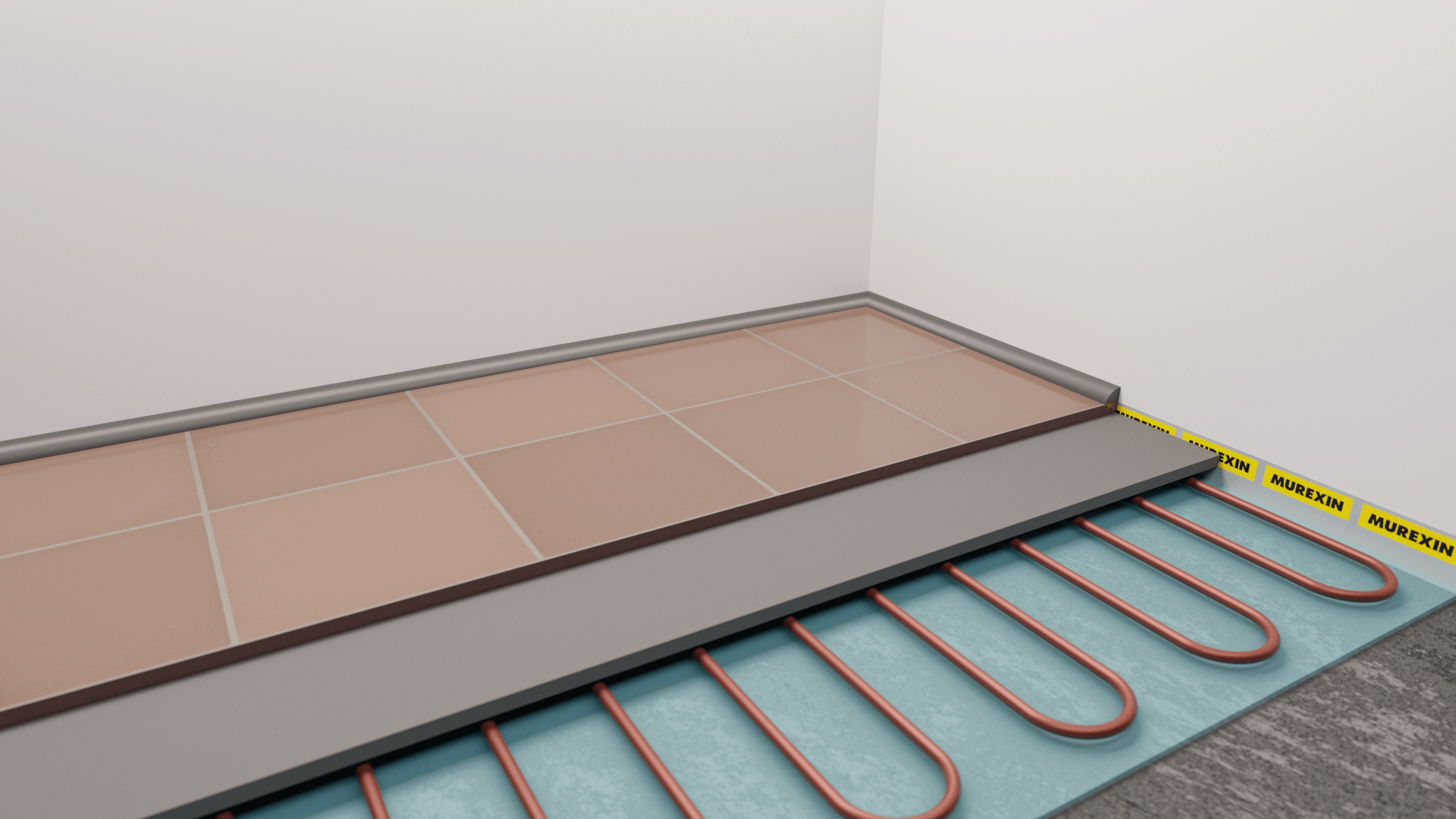

Furthermore, the substrate preparation with self-levelling filling compounds is of particular importance. On the one hand, they even out the tolerances of the substrate, e.g. as preparation for the installation of large formats, and on the other, they can also be used, for example, for height levelling or for grouting subsequently installed underfloor heating systems. The areas of application for self-levelling smoothing compounds are diverse; they can also be used in outdoor areas or in industrial flooring.

Self-levelling filling compounds have high compressive strengths, yet they are unsuitable as floating load distribution layers. Self-levelling filling compounds must always be applied in direct contact with the load-bearing substrate, e.g. in combination with a load-bearing screed. They are part of the substrate and are not part of the floor surface. Self-levelling filling compounds must be covered with the top layer as soon as possible after they have set or protected against moisture penetration by covering measures. Products with a high gypsum content are particularly sensitive to recurring moisture reabsorption/release and can crack. All filling or smoothing compounds are subject to expansion, just like the

substrate to which they are bonded. This expansion movement can be absorbed with a suitable surrounding insulation strip, which at the same time prevents, for example, the penetration of the filling compound between the existing screed and the building structure (avoidance of structure-borne sound).

PRIMER LF 1

PRIMER LF 1