Murexin

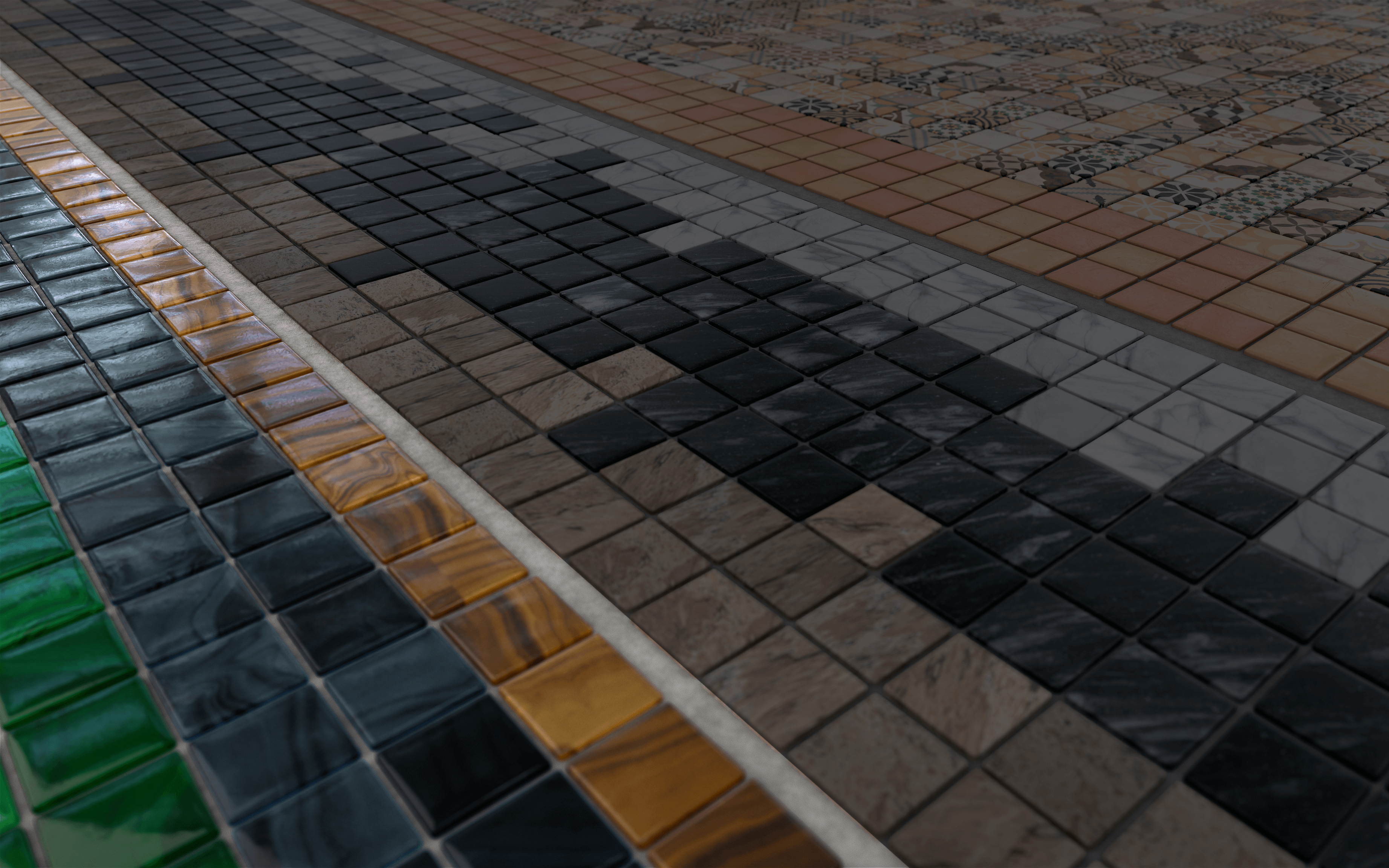

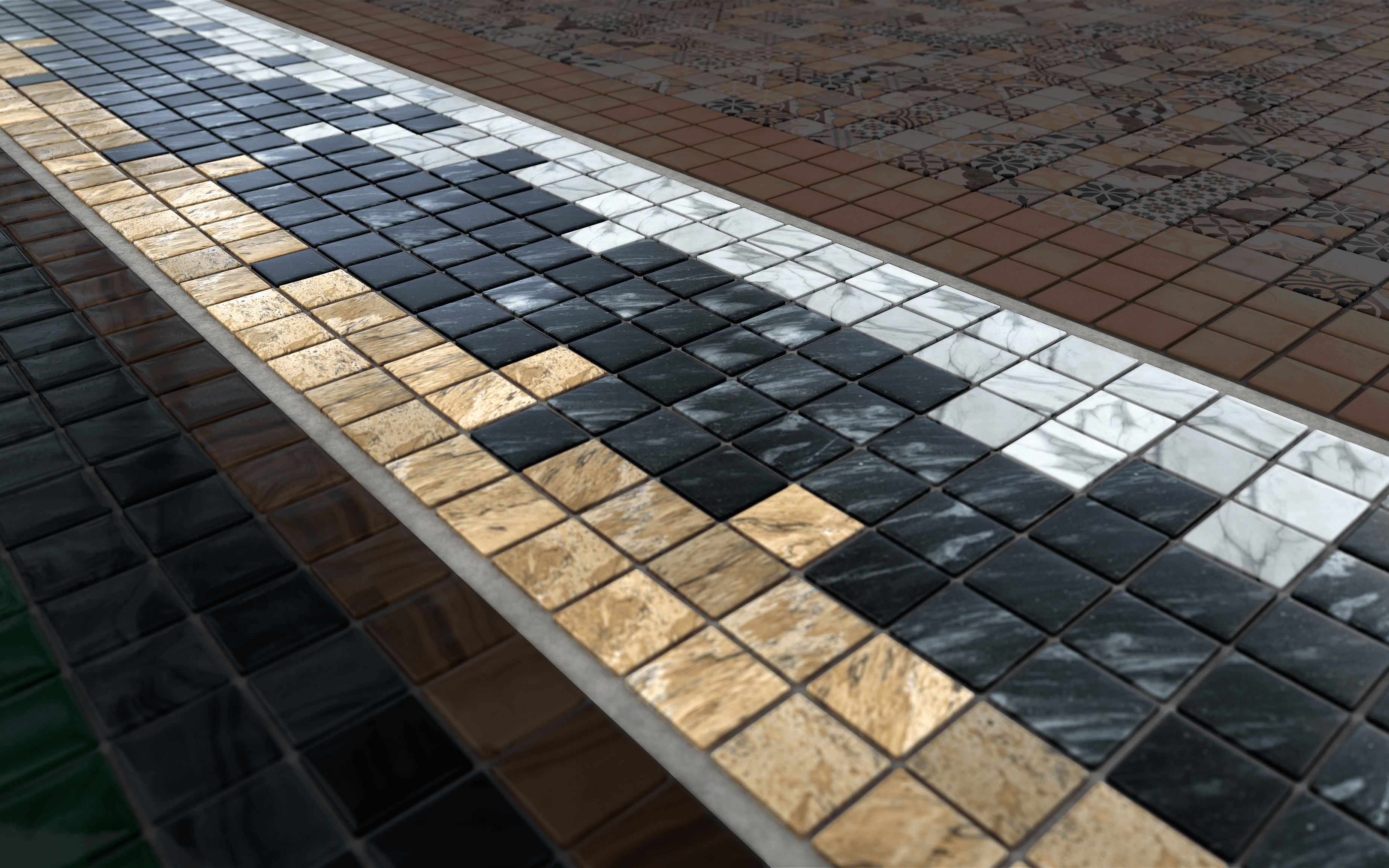

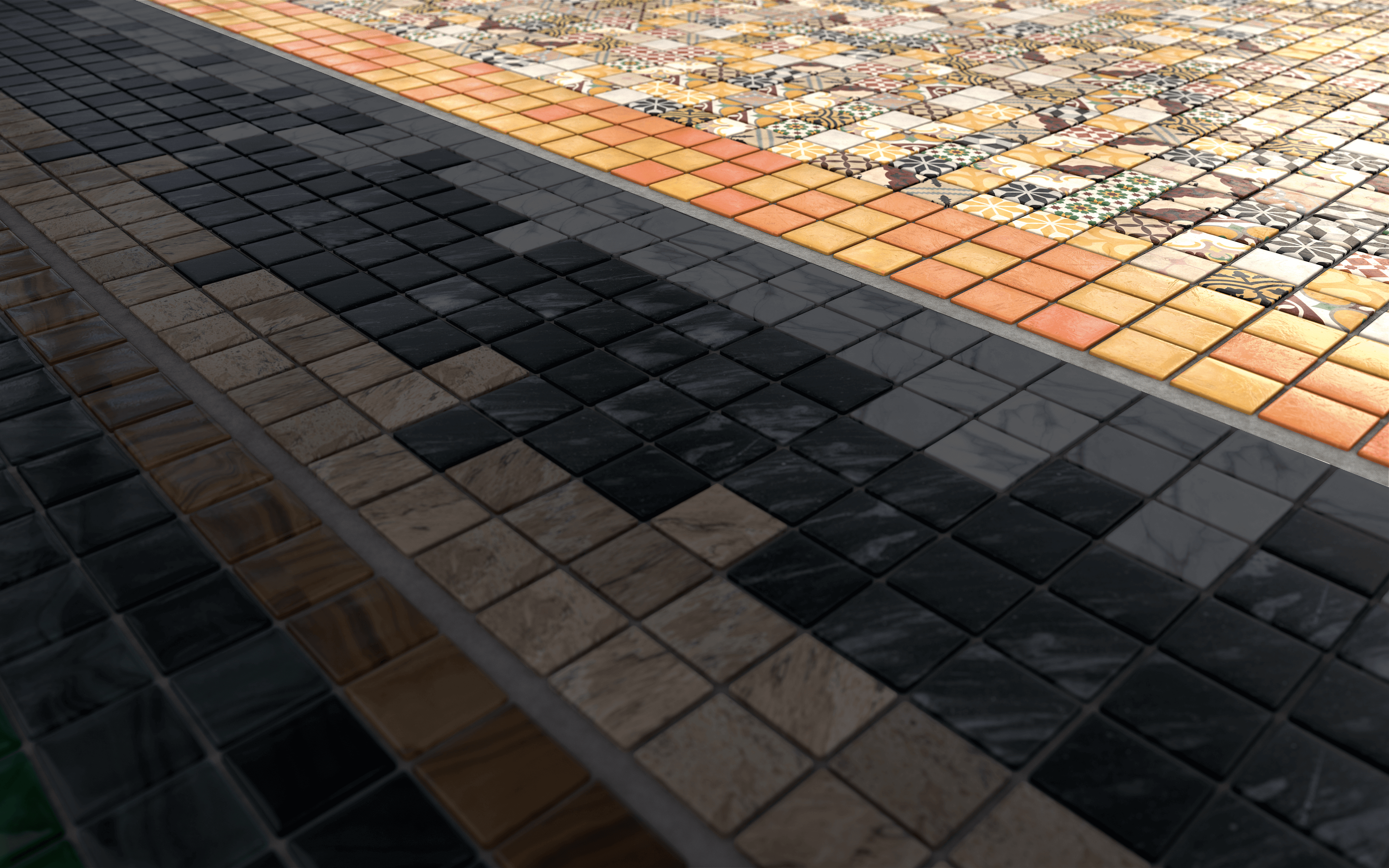

Tiling system structures

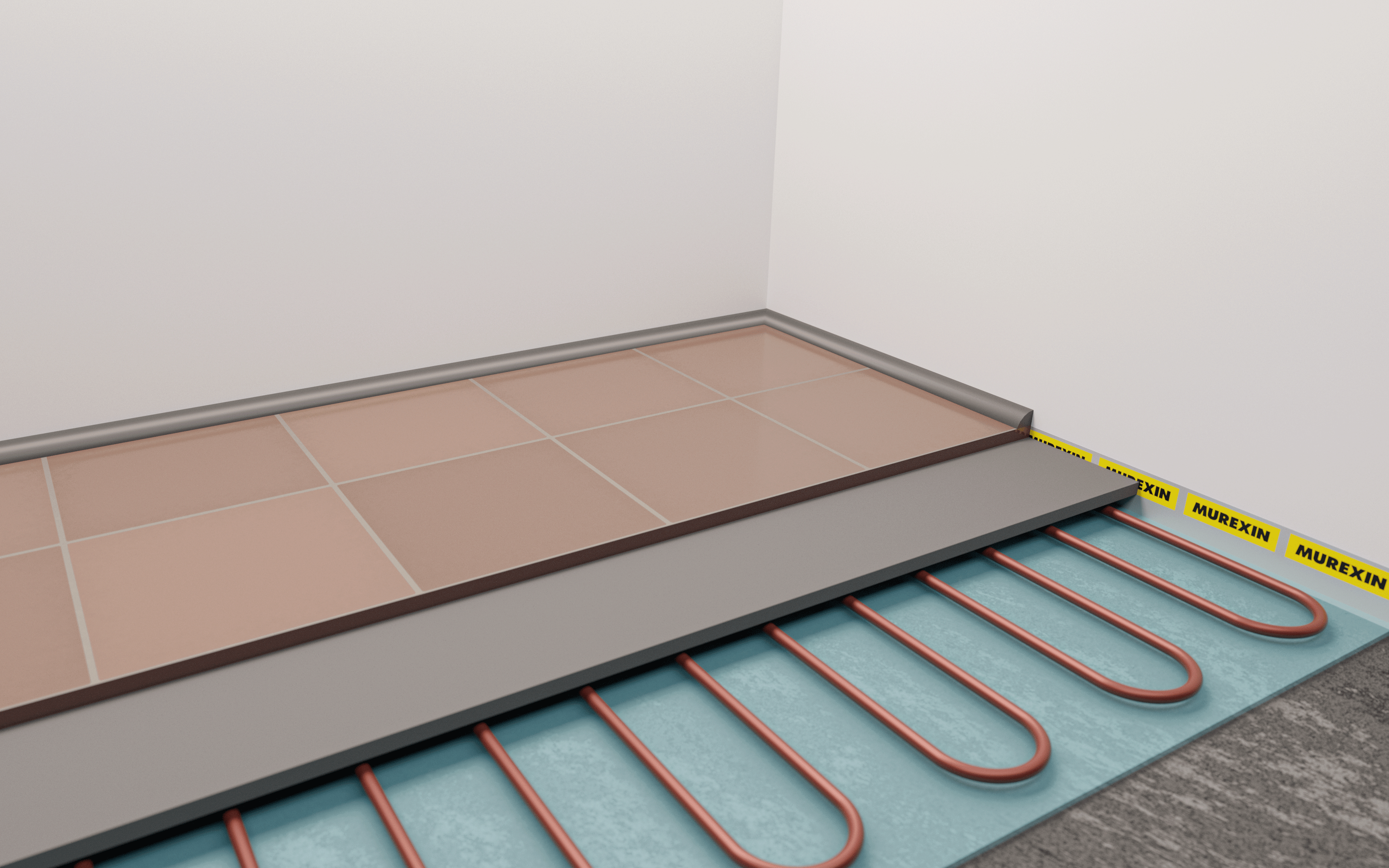

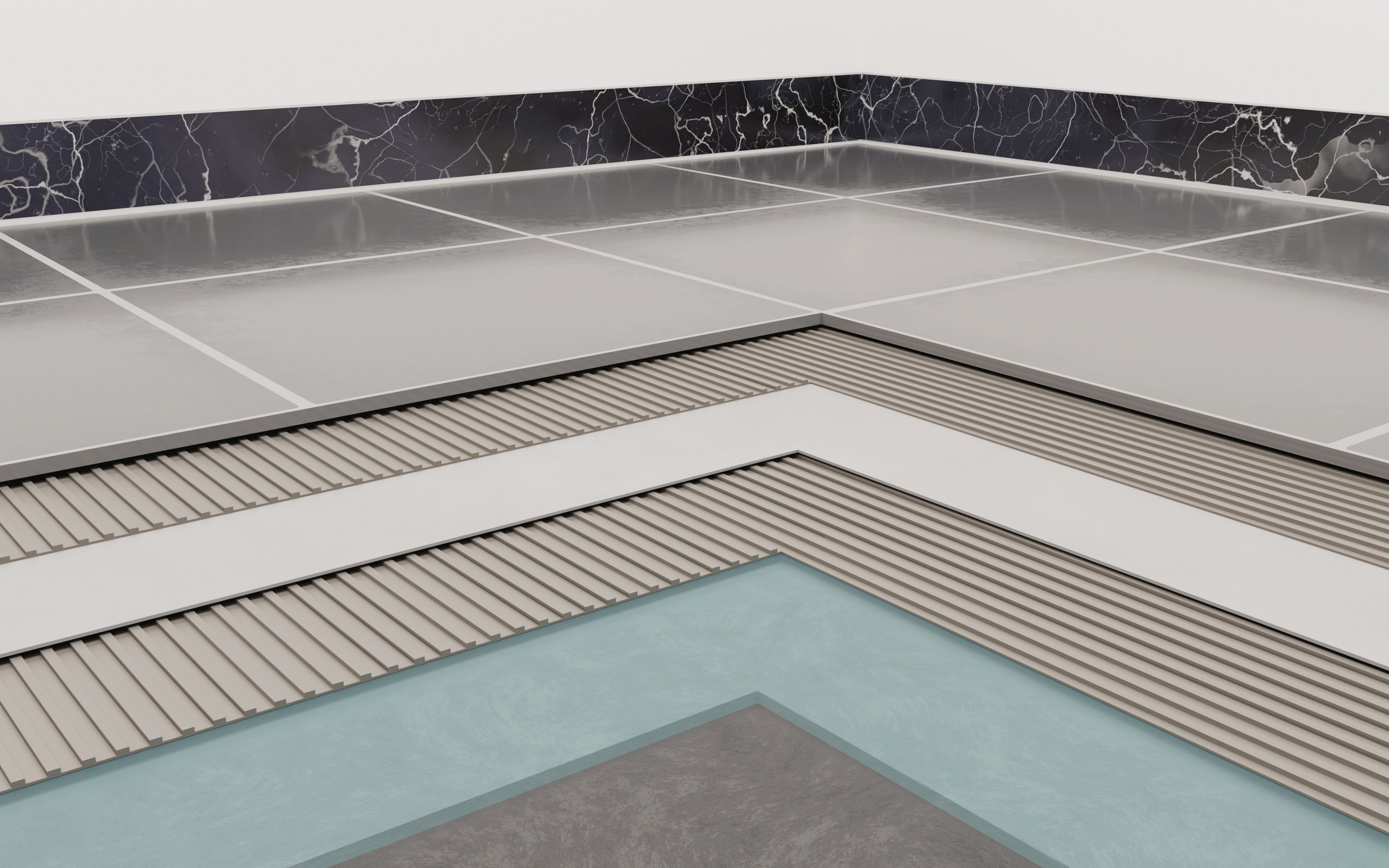

The areas of application for tiling are as varied and individual as the respective building site scenarios. Depending on the existing substrate, the area of application and ambient conditions, as well as the material and format of the installation material, different standards, regulations and implementation steps must be observed. A selection of frequently occurring areas of application and designs can be found in this overview:

Tiling system structures Germany

The designs described are based on current standards and regulations and include the experiences for practical application of our application engineers. However, they are for general information only and do not exhaustively illustrate all possible applications. We assume no liability for the correct implementation and performance of the projects.

bathroom setup with Uniplatte from Austrotherm

Every craftsman is familiar with the easy-to-handle, mortar-coated carrier and construction panels. These fabric-reinforced XPS panels are particularly popular in the field of tile setting technology because they are quick and easy to process and work. They are often used as partition walls, round shower walls, insulating wall substrates, cladding for bathtubs, prefabricated shower boards, shelf boards and so on as a supporting substrate for ceramic tile coverings. Murexin offers this thermally insulating, waterproof, vapor permeable, frost-resistant and highly pressure-resistant construction panel in thicknesses from 4 mm to 10 cm – the Uniplatte-System.

If Uniplatte-panels are used in moisture-stressed areas with low, moderate and high water load from W0-I to W2-I (according to DIN 18534 – tilers waterproofing for indoor applications), they can be sealed solely via the butt joints. With low and moderate stress W0-I and W1-I it is sufficient to glue the Uniplatte-panels in the joint area with the system-tested sealant and adhesive X-Bond MS-D 81 and to fill the joint of the butt joint with the sealant. In the case of high water load (W2-I), the butt joints must be secured with the system products sealing slurry PSM 1K and sealing tape DB 100. Sealing of the area outside the butt joints is not necessary in any of the shown moisture-stressed areas, cause the Uniplatte-panels are inherently water-impermeable (density > 30 kg/m³).